Our production equipment

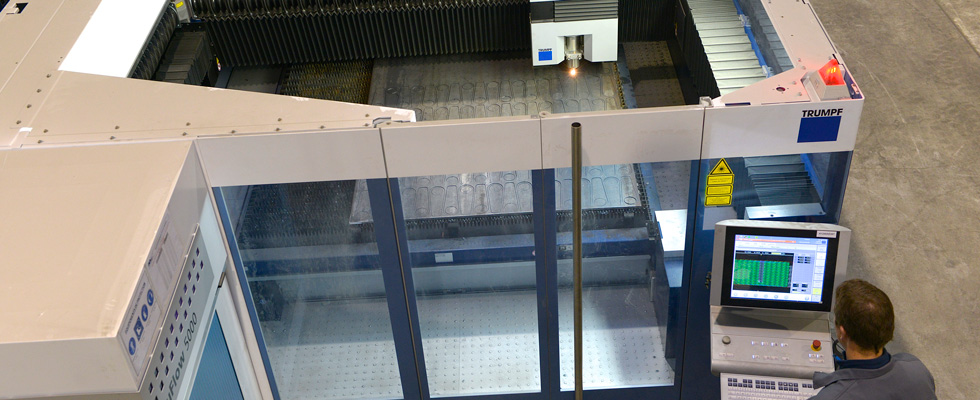

Laser Cutting

Laser Cutting

Our equipement

- 2 LVD machines (2500 W and 4000 W)

- 1 TRUMPF machine (5000 W)

Our capacities

- Maximum size: 4 m x 2 m

- Steel cutting: 0.5 mm min. - 25 mm max.

- Stainless steel cutting: 0.5 mm min. - 20 mm max.

- Aluminium cutting: 0.5 mm min. - 12 mm max.

- Marking (nitrogen, oxygen, compressed air)

- White cut 10 mm max.

Bending

Bending

Our equipement

- 3 LVD machines: 2 x 80 T and 1 x 220 T

- 1 TRUMPF machine (36 T)

Our capacities

- Max. length: 4 metres 220 T

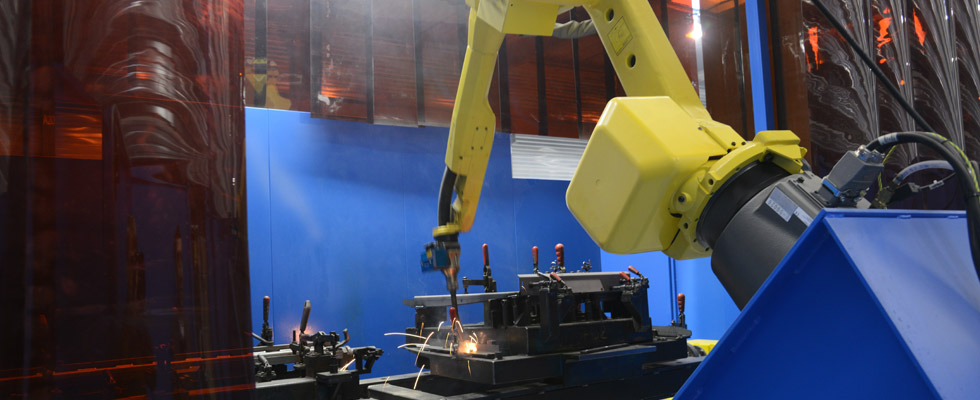

Welding

Welding

Our equipement

- 1 robot on a rail with 2 turners and fixed tables

- 1 robot on a rotating turntable with 2 turners

- 25 semi-automatic welding stations

- 1 TIG welding station

- 1 spot welding unit

- 18 welding enclosures

Our capacities

- Steel, stainless steel and aluminium welding

Grinding

Grinding

Our equipement

- 4 grinder enclosures

- Angle grinders

- Random orbit sanders

Our capacities

- Finished product for painting

Verification / Quality control

Verification / Quality control

Our equipement

- 1 FARO arm: portable machine that verifies the quality of parts by performing 3D inspections with a precision of 0.05 mm.

- 1 WELDSCANNER: portable device that analyses welding parameters (gas flow rate, wire feed speed, tension, amperage)

Other

- 1 tapping arm (M3 to M12)

- 1 shearer (4 m), 6 mm max. thickness

- 1 radial drill, 40 mm max. diameter

- 1 bandsaw

Laser Cutting

Laser Cutting Bending

Bending Welding

Welding Grinding

Grinding Verification / Quality control

Verification / Quality control